Roland DWX-52DCi Disk Changing Dental Mill

The DWX-52DCi 5-Axis Disk Changing Dental Mill

The DWX-52DCi is designed for effortless, precision production of dental prosthetics from copings, crowns and bridges to inlays, onlays and abutments, etc. With a host of automated features and a clean, stable work environment, is the perfect solution for labs wanting to increase production or those looking to get into digital milling for the first time.

Feature Summary

- 5-axis simultaneous milling for precision milling

- 6 Disk Changing Mechanism (ADC)

- Steady and efficient ball screw-driven operation

- 15-station Automatic Tool Changer (ATC) for continuous milling

- Powerful vacuum and anti-static ionizer for clean calibration and dust reduction

Built-to-Last

For thirty years, Roland DG has been the trusted provider of milling machines that are built to last. The DWX-52DCi 5-Axis Dental Milling Machine is no exception. After extensive research in which lab technicians were asked what they needed in a production mill, the DWX-52DCi was developed to enhance user experience, maximise ease-of-use and improve output quality. Built with a simple and modern design, the DWX-52DCi looks as effortless as it operates.

Ultimate Convenience and Ease-of-Use

A variety of new features ensure continuous, user-friendly milling, including:

- Sturdy frame ensures stability, while slim design fits nearly any lab space

- Easy access tool drawer properly stores and protects tools

- Colour-coded LED status lights signal current job progress

- Virtual Machine Panel (VPanel) allows users to configure settings from their computer, send CAM data to the DWX-51D for production, and track milling progress

- Easily accessible cutting area for simple tool replacement and cleaning

Compatible with Multiple Materials

The DWX-52DCi is equipped to mill industry-standard discs and blocks of these and other popular materials.

- Zirconia

- Wax

- PMMA

- Composite resin

- PEEK

- Gypsum

Roland DG supplies a variety of tools to mill different materials, including diamond-coated burs and ball-end tools designed specifically for precision milling of zirconia and hybrid ceramic.

Combine DWX Devices for a Flexible Dental Solution

The DWX-52DCi offers the best performance and value for dry milling zirconia and other popular materials. For those wanting to combine dry and wet milling, running the DWX-52D dry mill alongside the DWX-42W wet mill offers the most flexible and productive solution.

Using separate dry and wet DWX devices gives you the confidence to take on the maximum amount of glass ceramic and zirconia restorations without the need for time-consuming, back-and-forth set-up and cleaning of a single machine.

5-Axis Machining for Smoother Production

The DWX-52DCi is a smooth and steady ball screw-driven machine capable of milling complex restorations. It operates on X,Y, and Z axes – simultaneously rotating blocks and discs. Tilting on the B axis it supports deep undercuts and the complex milling of large arch restorations and other full-mouth prosthetics.

Economical Open Architecture

The open architecture of the DWX-52DCi allows you to work with the latest materials, CAD/CAM software and scanners, without needing to rely on a single source.

Clean and Comfortable Operation

A unique inner structure with spacious airflow supports comfortable operation, while an automatic dust collection feature boasts a powerful vacuum for clean usage and calibration. An ionizer removes static, ideal for milling PMMA material.

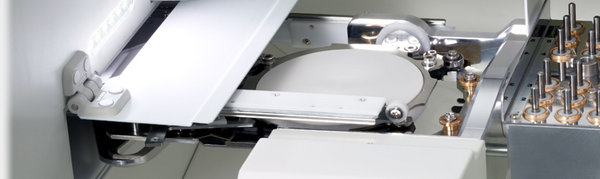

Auto Disk Changer (ADC)

Load the six O-Clamp material adapters with different shades of zirconia or any combination of material discs to suit your needs. Assign them with milling jobs and let the automatic disc changer do the rest.

Material adapters can be individually labeled and barcoded to enable VPanel recognition of each disc position. Organize job assignment via your CAM software for non-stop production..

15-Station Automatic Tool Changer for Continuous Milling

With a 15-station Automatic Tool Changer (ATC), DWX-52DCi users don’t have to stop production to replace the specific burs needed for milling different materials.

Virtual Machine Panel

Complex controls associated with CNC milling have been replaced by a user-friendly Virtual Machine Panel (VPanel) that automatically starts the milling process, conducts machine diagnostics and operates milling calibration from your computer.

Progress and Error Alerts

To further automate the milling process and ensure error-free production, users receive e-mail notifications detailing any errors, or when milling is completed, while a colour-coded LED light signals machine status

9 Pin-Type Material Adapter Included

A material adapter with nine pin-type placement options is included for easy and error free set-up.

Optional CAM Software

Open-architecture CAM software that accepts all STL file types and supports the milling of relevant materials is optional with the DWX-51D. This easy-to-use software features a user-friendly interface and simple workflow that promotes a short learning curve. Its features include automatic nesting and placement options to help maximise efficiency and pre-defined milling procedures for direct software-to-mill functionality without interruption during tool path calculation.

Peace of Mind

The DWX-52DCi offers unmatched reliability with the best warranty and post-sales support in the industry. Enjoy the benefit of certified service engineers that ensure your device is always up-and-running and a dedicated online and telephone support staff who can answer all your questions and concerns.